OfferUmola Sp. z o.o. specializes in the design and production of professional assimilation lighting systems dedicated mainly to greenhouse crops and vertical farming facilities. The philosophy of our business is to offer our clients tailor-made solutions - taking into account their individual needs and expectations.As a result, we develop LED lighting systems, that are distinguished by a competitive investment cost. Morover energy consumption is optimized while achieving ideal parameters for the proper development of cultivated plants. Below we present all steps of our operation methods that allow us to approach each facility and most of crops’ type in flexible way.

1. LAMPS' CONSTRUCTIONDepending on the purpose of the lighting system, we approach to our lamps’ construction in two ways: HIGH POWER LAMPS These lamps dedicated to large-area greenhouse crops. Such luminaires are distinguished by: |

|

|

Such design allows us to use a maximum power of nearly 1000W per LED lamp and places it in the smallest housing 30x20x15 cm that is currently available on the market. This, in turn minimizes the shading effect. The optics that we use in this model are lenses made of PMMA and/or specialized glass with anti-reflective coating on both sides.

LOW AND MEDIUM POWER LAMPS IN A LINEAR LUMINAIRE

|

|

| Top-lighting lamps are designed with the use of an anodized aluminum structure of appropriately selected physical parameters of the heat sink. The optics were prepared with the use of highly translucent PMMA. The above solution means that our luminaires distinguishes with a very high parameter of light efficiency (mmol / W). Linear lamps can be an excellent alternative to high-power lamps in less demanding crops and in objects with a limited construction height above the tops of plants. |

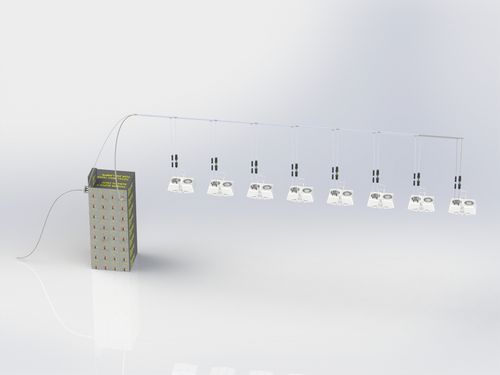

LIGHTING SYSTEMS DEDICATED TO VERTICAL FARMING FACILITIES

|

The idea of vertical farms assumes that plants are grown in specially desgined chambers, which eliminates the influence of external conditions. The cultivation thus becomes independent of the climate and weather conditions. The "vertical farmer" does not have to worry that his crops will be damaged by drought, frost or hail. On the contrary, it can be sure that the growing season is uninterrupted throughout the year. Our proprietary solution is based on the meticulous design of the luminaire and the use of the highest quality components. The above concept allows you to adjust both the physical parameters of the luminaire, such as the length or width of the lamp sets, and the lighting parameters related to the light spectrum, luminous flux (expressed in micromoles), the power of the luminaires and, what is important, the uniformity of lighting. Thanks to this flexible approach, we are able to prepare a system for almost any facility. In view of above, we can adapt our lamps to various types of object’s structures and create ideal conditions for the development of most vegetables, fruits, herbs and other low-growing plants. |

|

2. POWER SUPPLY

Depending on the client's expectations and the specificity of the facility, we can approach to the power supply issues of our lighting systems in two ways:

LOCAL/TRADITIONAL

|

This approach is based on "plug and play" system, which means that each lamp or possibly a group of several lamps is powered by a dedicated LED driver located in the housing of each luminaire or in a separate housing attached to the structure of the facility. This approach is most appropriate in cases where the existing electrical installation is already available in the facility. |

CENTRAL POWER SUPPLY

|

When a new investment arises, we can consider the use of a central power supply located outside the cultivation area. In this case, we use special power hubs consisting hundreds of kilowatts. However, this approach requires the design and implementation of a dedicated electrical installation. Therefore, the use of a central power supplier is often the best solution for vertical farming. Moving the PSU outside the growing area gives you better climate management options. The solution we use also allows the integration of the lighting system with a climate computer, e.g. of the PRIVA type. |

|

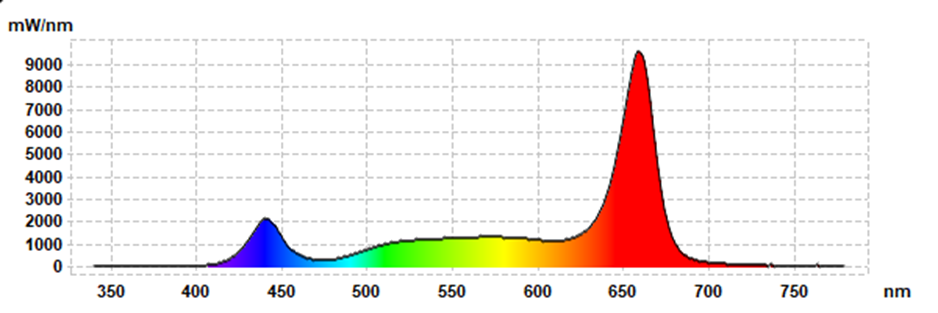

3. LIGHT SPECTRA

One of the key aspects of horticultural lighting systems is the light spectra. It depends on the type of crop we deal with and on the stage of development of our plant.

Put it simply, different plants require a slightly different light spectra. The light range should be different for the seedling during its first phase of growth and development, and different for an adult plant that is in its flowering and fruiting cycle.

The light spectra also has an enormous impact on the comfort and quality of work of people staying in the facility. Where we harvest e.g. tomatoes, peppers or strawberries, we must be able to assess whether a given fruit is already suitable for harvesting and then, the CRI color rendering index should be at a relatively high level. Where there is no need to conduct the so-called visual inspection, we can use light with a slightly more aggressive “pink tint”, which has a more stimulating effect on the development of plants.

Thanks to our several years of experience working together with growers, we are able to propose and adapt appropriate solutions in the field of the light spectra ideal for a specific crop, thus responding to the individual expectations of our customers.

4. DESIGN OF LIGHTING SYSTEMS FOR DIFFERENT CROPS

|

The key stage in the implementation of any lighting system is its correct and ingenious design. Thanks to this, on the one hand we get an optimal system for our plants and its proper development, and secondly, we are able to optimize it in terms of costs. Thus, a properly designed lighting system will allow the grower to achieve his business goals both on the revenue side and on the cost side of such investment. |

|

Thanks to our experience in the implementation of various types of lighting projects and a flexible approach to the construction of designed devices, we can meet even the most difficult challenges. The lighting project is very helpful to verify all parameters of the proposed devices. Final result comes from a simulation that is made in a computer program reflecting the targeted object/facility. The data obtained through such a computer simulation are practically identical to the later real effects obtained after the implementation of the lighting investment. During the above design and simulation works, we are able to tell the client exactly what parameters of the lighting will be obtained and to target cost of the solution we propose. The very stage of our project implementation does not involve additional costs. In other words, the client receives it free of charge as it is calculated in the final price of eventual investment. |

5. COMPONENTS

|

While producing, we use only the highest quality components from reputable manufacturers, which give us the certainty of failure-free operation in such demanding environments as greenhouses or vertical farms. We use materials and components from the following suppliers:

|

|

The development and production of lighting systems dedicated to plants additionally requires a non-standard approach from their designers. Due to the fact that, as a rule, the concepts of plant assimilation lighting are usually complex systems, so they consume a lot of power energy. Therefore, it is important that the designed solutions ensure the highest possible light efficiency and thus reduce power consumption. Therefore, not only the LEDs, optics or power supplies themselves play a key role. The entire temperature management is extremely important. Our products are equipped with high-class aluminum circuits (MCPCB) suitable for mounting high-power LEDs. In addition, all substrates (PCBs) are covered by us with special thermally conductive pastes with a high thermal conductivity coefficient.

All our lamps are designed and produced on site in Poland, going through the stages of tests, laboratory measurements, up to the production and installation at the customer's site.

6. SYSTEMS WITH CHANGEABLE LIGHT SPECTRA

|

For the purposes of getting in knowledge within a hortilighting market, we have developed specialized systems with variable light spectra. These systems are dedicated to research and scientific institutions and to those growers who look for the right light recipe that will stimulate their crops and provide ideal conditions for the development of specific plants. Thanks to systems with a variable spectrum, the customer will be able to smoothly adjust both the light spectrum in the entire PAR range and the power of the luminaires depending on the reactions of the plants subjected to illumination. |

The effect of such a study are individually defined lighting conditions for a specific crop in a specific place. Based on this, there is a further possibility to design a commercial lighting system on a larger scale.

7. KEY LED LIGHTING PARAMETERES

While designing growing lighting systems for crops, there are several key parameters of the system that should be taken into account in order to obtain a modern optimized solution. It always shall meet the expectations of even the most demanding plants and growers themselves.

Below is a short list of key parameters that each investor should pay attention to when planning an investment in LED lighting:

-

LIGHT FLUX EFFICIENCY expressed in the number of micromoles per one Watt, as of today should not be lower than 2.5 mmol / W. Luminaires with low efficiency require a lot of energy and provide a relatively low luminous flux.

-

LIGHTING UNIFORMITY at the plant tops from a certain height related to the structure of the object. It is measured as the lowest value of the intensity PAR mmol.m2 / s to the average value on a given area. The indicator given in this way should not be lower than 70%. At lower values, the crop’s development will not be even and there will be a clearly visible difference between better and less enlighted plants.

-

LIGHT SPECTRA adjusted to the specific type of plant and stage of development. For example, the range of blue light waves in the range of 400-500 nm - its increased level is beneficial at the seedling stage (among other things, it causes better rooting and thickening of the stem), however, as a further consequence, it may limit its growth in the case of an adult plant. In turn, the so-called red light radiation in the range of 600-700 nm has a very positive effect on the elongation of the stems as well as flowering and fruiting of plants.